EEF Particle Filter System

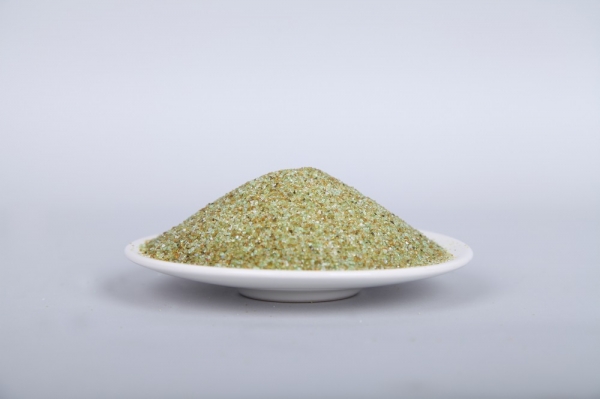

"Energy Efficient Fine" Particle Filter System is used to improve the performance of traditional mechanical filter, which can reduce the workload of RO membrane. When the water passes through the filter from top to bottom, compared with traditional filter, the new type filler inside can significantly reduce TSS and turbidity, and the loss of pressure is lower. The filter can be made of FRP, carbon steel, stainless steel and other materials.

| Traditional Filter System | EEF Particle Filter System |

| Easy to become a biological filter bed, breeding bacteria | Antibacterial,reduce fouling chance |

| Disinfectant required | Significantly reduce or no need the use of disinfectants |

| Disinfection by-products need to be controlled | Reduce disinfection by-products (Trichloroammonia) |

| Pit hole or agglomerate | Prevention of pit hole and agglomerate |

| Low filtration accuracy (no flocculation) | Precise filtration down to 1 micron (no flocculation) |

| Change every 2~3 years | No need for replacement, Reduce Total Operating Cost |

| Unverified & Uncertified | Verified and Certified by NSF 50&61 listed media |

| Filter material varies greatly | Stable quality (production under ISO) |

| Low filtering quality | Predictable filter performance |

| Low filtration flux | High filtration flux |

- Reuse of Electroplating Wastewater

- Reuse of Wastewater after biological process

- Raw Water with excessive Iron and Manganese

- Raw Water with high turbidity

| Model | EEF-5-E | EEF-10-E | EEF-15-E | EEF-20-E |

| Capacity | 5m³/H | 10m³/H | 15m³/H | 20m³/H |

| Barrel size(Inch) | Φ30*H72 | Φ42*H72 | Φ48*H72 | Φ63*H86 |

| Backwash time | 3-10min | 3-10min | 3-10min | 3-10min |

| Effluent pH | 3-9 | 3-9 | 3-9 | 3-9 |

| Maximum differential pressure | <0.5bar | <0.5bar | <0.5bar | <0.5bar |

| Water temperature | 1-100℃ | 1-100℃ | 1-100℃ | 1-100℃ |

*Designed according to conventional water quality,please consult SCHW for special requirements

苏公网安备32011502012526

苏公网安备32011502012526