LCD Industry

At the LCD production, silicon needs to contact ultra-pure water directly on more than 50% processes. Additionally, more than 80% processes need chemical treatment, which is closely related to ultra-pure water and contacts work pieces directly. The impurity of water will lead to the degradation of device performance, which will then influence the performance of products and product yield rate. Therefore, the quality of ultra-pure water has great impact on the development of LCD.

SCHW has been committed to develop water treatment industry for many years. We adopts advanced technology at domestic and abroad, combined with our unique process design, then according to the specific requirements and needs of clients, design the safe and stable ultra-pure water system that suitable for them. SCHW can help clients to solve the concerned indicators in ultra-pure water: conductivity and silicon.

- The cleaning of LCD

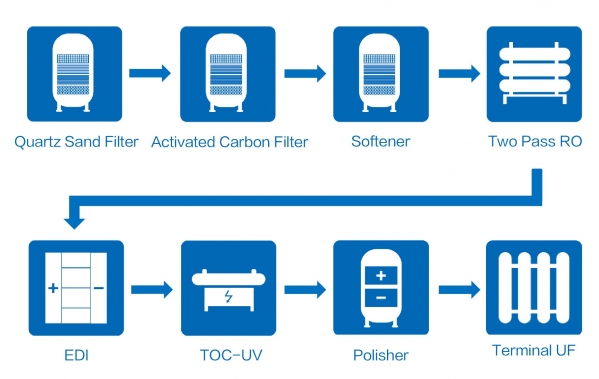

Process Ⅰ:

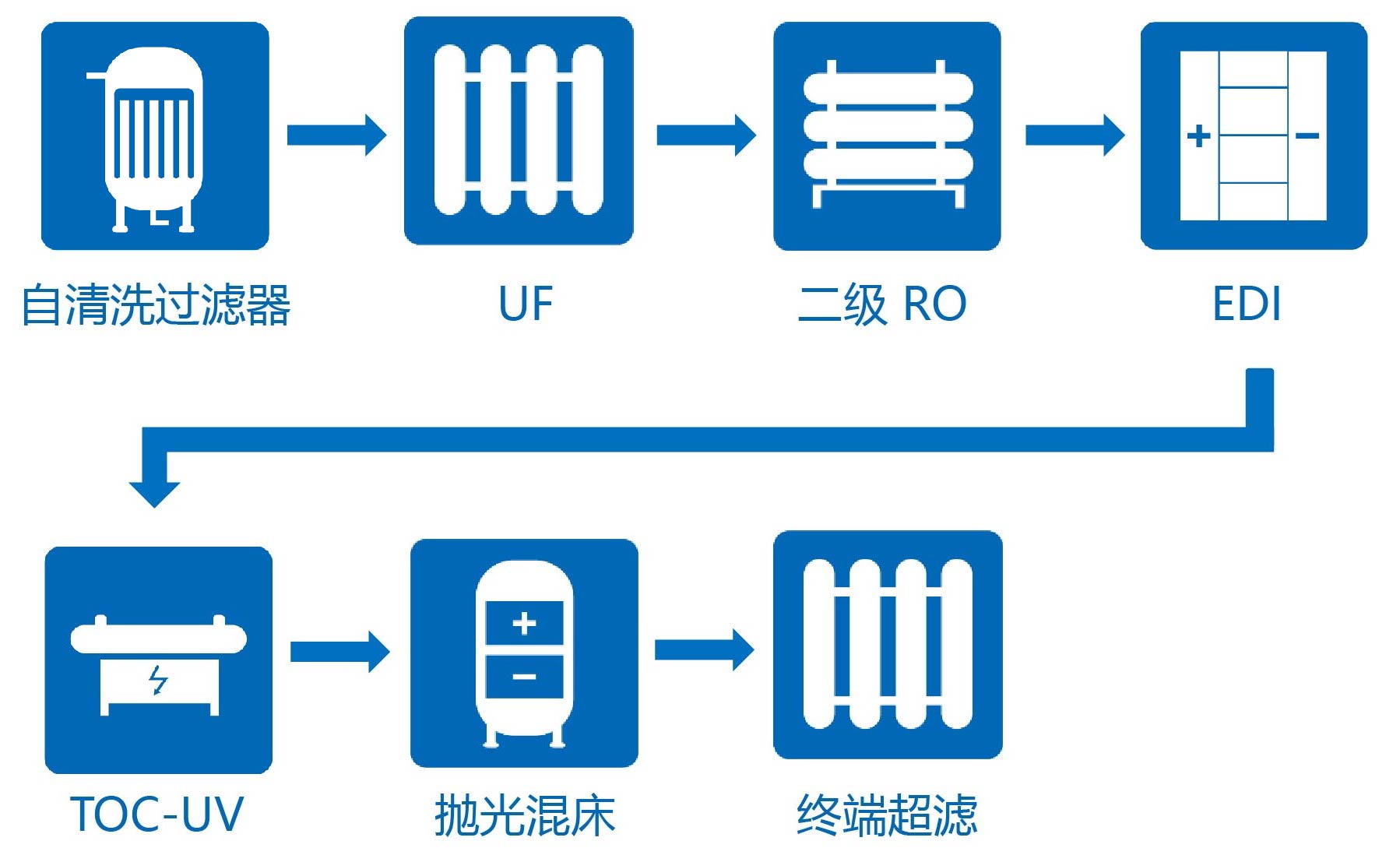

Process Ⅱ:

Process Ⅲ:

- According to the unique requirements of water usage and equipment, SCHW can provide industrial design and customized solution.

- Provide turnkey project – including design, engineer, manufacture, automation, installation, maintenance and training.

- Leading technology, rich experience, effective and reliable water treatment and wastewater reuse.

- Perfect online support and on-site services.

苏公网安备32011502012526

苏公网安备32011502012526